In principle, deposit soldering is a process variant of soldering which can be classified as high-temperature soldering. It is a thermal process which is carried out either without flux in a vacuum or under inert gas with solders with a liquidus temperature generally above 900 °C. The special feature of deposit soldering is that no components are firmly connected to each other, but a metallic coating is created by applying solderable materials.

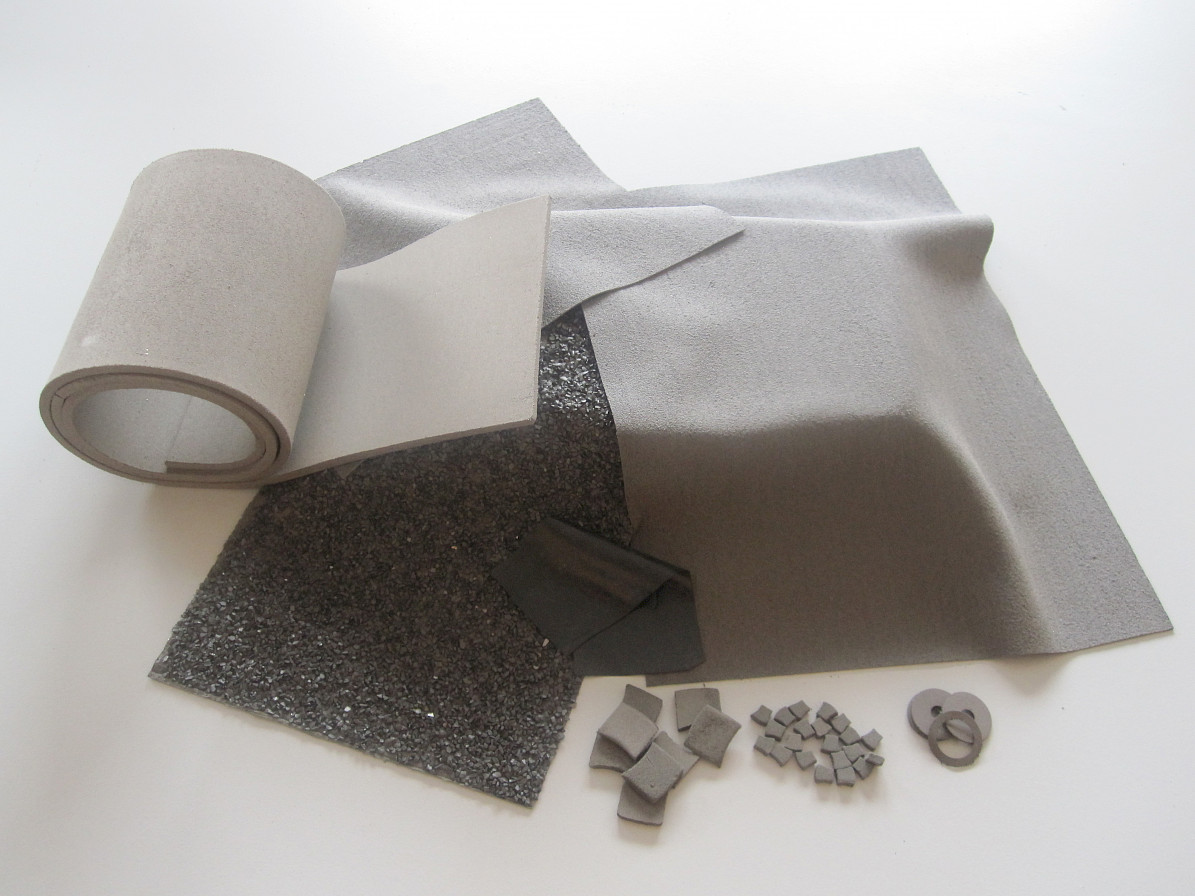

The most frequently used solder matrix materials are nickel, cobalt, iron and copper-based solders or corresponding alloys. Hard materials are mixed in depending on the coating function. Carbides, borides, silicides, diamonds, oxides, CBn or hard material mixtures can be used as hard materials. Well-established hard materials are WC, CrC or NbC.

The coating produced during deposit soldering can take on various functions, which is why it is also called a functional coating. For example, hard material particles that have been introduced into the solder can be firmly soldered onto the component surface. In this way they take on a wear protection or gripping function. By soldering and reworking suitable materials as a tape into the wear areas, worn components such as turbine blades or molds can also be reconstructed, for example. Since the coatings are very dense and crack-free, they are also ideal for corrosion protection even at high temperatures. The deposit-brazed coatings are relatively smooth and - in contrast to deposit welding - often do not need to be reworked or ground.

Tapes are produced by mixing and homogenising, adding binders, shaping and calibration. Thanks to the special shaping technique, binder contents of less than 3 % can be achieved. The outgassing of lower binder contents in the heat treatment process is particularly advantageous here. This is because the lower the number of binders used, the higher the quality that can be achieved in terms of coating adhesion and porosity. Hard material proportions in the coating can be up to 80 vol.% and higher. Coating matrix hardnesses of between 20-30 HRC and 62-65 HRC can be achieved flexibly.

The tapes are applied to the surfaces after they have been manufactured, in order to subject them to a heat treatment. The heat treatment causes the solder contained in the tape to react with the hard materials embedded in it to form the desired wear protection layer. High-temperature brazed hard material layers often achieve the same strength as the base materials, so that the result is a highly stressable hard material layer-base material composite. The coating of 2D and 3D geometries is possible both inside and outside. Layer thicknesses are usually 1.0-2.0 mm, whereby minimum layer thicknesses of 0.05-0.1 mm up to 10 mm and more can be achieved.

For many years EUROMAT has been developing and producing brazed coatings for a wide range of applications such as plastics processing, turbine construction, power plant technology, earth+stones+wood, and mould and tool making. BodyClad© from EUROMAT GmbH is an innovative surface concept for the coating of new parts and repair by brazing.

|

|